Environment

CO2 emissions & energy

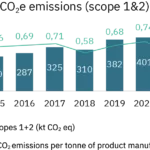

Convinced that a sustainable activity in the pharmaceutical or cosmetics sectors must necessarily propose an ambitious decarbonization trajectory, the SEQENS Group has been fully mobilized since 2008 to accelerate its low-carbon transition and reduce its greenhouse gas emissions. This historic commitment, involves measuring its CO2e emissions, defining ambitious reduction targets and implementing concrete actions at all its industrial sites. This is all the more important in view of the constraints linked to the increasing scarcity of fossil fuels, the rising cost of energy and, of course, the challenge of climate change.

- Reduce CO2e emissions per ton of product manufactured by 45% between 2011 and 2025 on scopes 1&2.

- Reduce energy consumption per ton of product manufactured by 10% between 2021 and 2025

- Achieve a 50% share of renewable and recovered energy by 2025

- Improve the energy efficiency of buildings, processes and utilities (consume less).

- Decarbonize the energy used (consume differently) by promoting the use of less carbon-intensive energy at our production sites (switching from coal to gas or electricity, energy recovery, on-site renewable energy production) or by purchasing certified renewable energy .

- Develop innovative processes and breakthrough solutions to reduce the carbon footprint of manufactured products.

With the pilot plant, over 10 tonnes of paracetamol have been synthesized, confirming the objectives of drastically reducing the environmental footprint of this product, with a 4-fold reduction in CO2e emissions for scopes 1 and 2, and a 3-fold reduction in energy consumption, with almost no effluents thanks to the regeneration of solvents.

Construction began in early 2023 and will be completed in 2025, with the first customers scheduled for delivery in 2026. »

Water

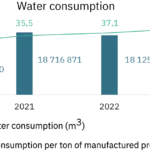

Water is an important component of SEQENS’ industrial activity. Utilities (steam, cooling water, process water, etc.) are by far the main use of water for the Group. It is thus mainly used as a vector for cooling or heating manufacturing processes.

Water is also used to clean equipment and networks between production campaigns, in order to comply with quality standards related to the manufacture of products.

However, not all resources are unlimited, and their industrial use must be controlled and limited as much as possible, especially in areas of water stress. In order to contribute positively to the preservation of water resources, SEQENS is committed to reducing its water consumption.

- The installation of closed loops, especially for the cooling of process equipment.

- Optimization of water consumption through the installation of new, more efficient equipment, automated systems, water-saving materials, etc.

- To gain a better understanding of the site’s water consumption, we have mapped the use of city and river water.

- Water consumption linked to the cooling of incinerator flue gases via the cooling towers has been reduced.

- The parameters of the cooling towers have been adapted to better match the outside temperatures. Cooling towers now have two temperature ranges (summer and winter).

- The production osmosis unit was removed and the network connected to the new boiler osmosis unit to optimize water consumption.

Waste

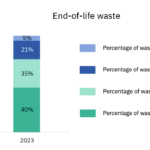

SEQENS’ production activities generate routine waste inherent to the manufacturing and packaging processes. Most of these wastes are hazardous wastes, in particular solvent-based liquid wastes.

In order to fight against the waste of natural resources and to limit the impact of production activities on the environment, SEQENS is committed in its EHS policy to preserve natural resources and to reduce at all levels the environmental footprint of products and processes.

SEQENS aims to reduce the quantity of hazardous waste generated, in particular the quantity of solvents consumed, and to improve the end-of-life of waste by promoting waste recovery (material or energy).

- Reduce the amount of waste generated

- Reuse directly or, recycle and reuse internally waste whenever possible (reuse as raw material or input in a manufacturing process). This is particularly the case for used solvents, which can be reused in the same production cycles.

- Recovering value from waste, in particular as an internal energy source.

- Recycle or incinerate waste with energy recovery via an external service provider to recover the waste content in the form of materials or energy.

This project will make it possible to use 1,000 tons of products already stored for this project as raw materials in another process, thus reducing the quantity of outgoing waste.

Pollution

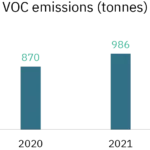

The manufacturing, storage and transportation of raw materials, products and wastes involve various risks of potential impacts related to the release of toxic chemicals on the environment and human health.

The Group systematically prevents the industrial risks of its activities, and in particular the environmental impacts on the sites where they are carried out, whether these concern the soil, water or air.

Each site has a general environmental analysis that must be updated regularly and whenever a significant change occurs. Any implementation of new equipment or manufacturing processes, or any change in industrial processes, is also subject to risk assessment and action plans to reduce potential impacts.

All activities performed by employees (permanent or temporary) are covered by an analysis of environmental aspects, including routine and maintenance activities. The preventive measures described in the internal procedures must be respected in order to avoid any pollution (soil, surface water, groundwater, air, etc.).

Response plans in the event of accidental events are in place and are the subject of training for the people concerned. The proper implementation of these measures is verified during preventive visits by insurers and during periodic EHS audits.

Depending on the site, if significant risks are identified or if regulations or SEQENS standards impose specific requirements, a more detailed assessment is carried out for the activities concerned. Appropriate action plans, or even immediate action if necessary, are implemented to reduce these significant risks to an acceptable level.

- Six French sites (Aramon, Bourgoin, Couterne, Saint-Fons, Villeneuve-la-Garenne, Limay) and two other European sites (Turku and Lahr) have submitted their re-examination dossiers for compliance with BREF WGC. This BREF WGC, which stems from the IED Directive (Industrial Emissions Directive), details the best available techniques (BAT) for gas emissions management and treatment systems in the chemical sector, and has become a binding regulatory reference.

- The Neot Hovav site has upgraded its air treatment system to reduce gaseous emissions. Water filters were installed and some of the system’s pipes and exchangers were replaced.